4

SATURDAY, SEP TEMBER 19, 2020 • KOKOMO TR I BUNE PROGRESS EDI T ION

Lori Thomas is carrying on a legacy, one

flower at a time.

Thomas is the owner of Flowers by Ivan

& Rick, a local floral business started by

her grandfather over 70 years ago.

Her grandfather, Ivan Mooney, was a

child of the Great Depression. At a young

age, he took a job as a delivery driver for a

florist. It was that experience that inspired

him to start his own business, where he

could try to brighten a person’s day with

each flower he gave away.

And he did give away quite a few flowers,

Thomas said.

“Grandpa would always give away flow-

ers for free,” Thomas said. “He knew it

wouldmake people feel happy and special,

and it was more than just what he could get

out of them. He likedmaking people smile

more than he liked making business.”

The business was always more about

making people smile thanmaking money,

Thomas said.

“Grandpa grew up in the depression and

he knew it was the little things in that that

matter the most,” she said.

Ivan Mooney worked in the business

until his death in 2013. Thomas said it was

his passion.

“He knew if he stayed home, he would

get older and stop moving around as

much,” Thomas said. “So he came in every

day.”

Thomas’s father, RickMooney, wanted to

actually retire. Rick Mooney ran the busi-

ness until a few years ago, when he passed

the business down to Thomas.

“Dad lived in here since he was little,”

Thomas said. “He watched grandpa put his

entire life in the business, and he realized

you don’t get to do a lot of other stuff when

you do that. He was like ‘I’m going to enjoy

my life.’”

Thomas has seen some big changes to

the floral industry since her grandfather

ran the shop. The internet is the biggest

game-changer, she said. With an online

presence, people can see the store’s floral

arrangements and novelties without hav-

ing to travel to the store. She said even in

the few years since she’s been running the

business, she’s seen a major increase in

online sales.

The other big change, she said, is that

the shop is now entirely run by women.

Though her two sisters have passed away

and are no longer able to help her run the

shop, she still incorporates memories of

them around the shop.

“I like to put their colors, their style, into

what we do here,” Thomas said.

Thomas’s staff are an invaluable asset

to the store, she said. Her head designer,

Nina, has been with the store for over 20

years. Nina, along with the other team

members including Nina, Mary, Kay,

Syenna and Mark, all feel like family to

Thomas.

Over the years, as many things have

changed in the floral industry, Flowers by

Ivan & Rick has maintained much of what

makes the shop stand out. They still give

out free boutonnieres to men to match

their date’s corsage for dances, and they

travel further for deliveries than any other

florist in town, Thomas said.

For Thomas, the shop is a way to carry

on her family’s legacy and memory. She

hopes to one day pass the business on to

one of her daughters, but for now, she’s

continuing to carry on her grandfather’s

tradition of making people smile with each

and every flower.

Flowers by Ivan & Rick is located at

404 E. Harrison St. in Kokomo, and

their arrangements can also be viewed

and ordered online at

ivanandrick.com.

BY CARSON GERBER AND

TYLER JURANOVICH

KOKOMO TRIBUNE

O

n Aug. 31 local workers

shipped out the last venti-

lators from the Kokomo

General Motors Components

Holdings plant to the U.S.

Department of Health and

Human Services, fulfilling the

$489.4 million contract awarded

to the company in April.

In just 154 days, workers

produced 30,000 Ventec Life

Systems ventilators from inside

the GM facility to add to the U.S.

Strategic National Stockpile. The

effort ensured hospitals around

the nation had access to the

life-saving machines during the

COVID-19 outbreak.

Workers cheered as they

packed up the final load of ven-

tilators, which were signed by

employees and staff at the plant.

Ian Cartier, a robotic techni-

cian at the facility, said seeing

the last ventilators ship out was

inspiring, and demonstrated

local workers’ dedication to

fighting COVID.

“All of us chose to leave the

security of our homes and give

110 percent every single day to

build ventilators,” he said in a

release. “We came in with the

attitude that for every challenge

we were handed that day, that we

would face it, fix it and overcome

it. That collective attitude has

brought us to where we are

today.”

The partnership between GM

and Ventec to build ventilators

gained nationwide attention.

The local GM plant was a regular

feature on national news

programs, and garnered a visit

from Vice President Mike Pence

in April.

“It’s amazing to think this floor

was empty about a month ago,”

Pence said at the plant. “Standing

here in the Hoosier State among

people who put together this

ventilator facility in 17 days ...

and in a matter of a month have

provided more than 600 ventila-

tors for the American people, I

couldn’t be more inspired.”

While at the plant, Pence was

given a tour and was shown step-

by-step how the ventilators are

made and talked to a handful of

local workers.

President Donald Trump, who

ordered GM to build the ventila-

tors in March under the Defense

Production Act, called Kokomo

a “great place” during his daily

briefing on the COVID-19

pandemic, and praised the

company for using its Kokomo

plant to make ventilators.

The move to fire up mass pro-

duction of the machines marked a

lightning-fast turnaround for GM

and the Kokomo facility. In less

than a month, the company had

transformed the factory, shipped

in all the parts required to make

the ventilators and implemented

extensive health and safety proto-

cols in the workplace.

“Our drive to put critical care

ventilators into production was

fueled by thousands of people

at GM, Ventec and our suppli-

ers who all wanted to do their

part to help save lives during the

pandemic,” said GM Chairman

and CEOMary Barra in a release.

“It was inspiring to see so many

people achieve so much so

quickly.”

The collaboration between

Ventec and GM to build V+Pro

critical care ventilators began

with a conference call on March

17. The first units were delivered

about a month later to Fran-

ciscan Health Olympia Fields

in Illinois and Weiss Memorial

Hospital in Chicago.

Dr. Suzanne Pham, the hos-

pitalist at Weiss Memorial

Hospital, said the facility is

still using the ventilators they

received in April that were

shipped from the Kokomo plant.

“The devices built in just one

month are currently helping

patients battling COVID-19, and

are valuable tools enabling our

medical team to save lives,” she

said in a release. “I’m proud to

say we have had many patients

beat COVID-19, wean off the ven-

tilator, and safely return home.”

One of those patients was

Jeffrey Dickerson of Chicago.

He said he couldn’t walk without

catching his breath when he

was rushed into a hospital room

earlier this year. He said it was a

ventilator made in Kokomo that

helped save his life.

“The team at Weiss put me

on one of your machines, and

I was fortunate to make a fast

recovery,” Dickerson said. “They

later told me they were running

out of ventilators, but fortunately

had received one of the first

shipments from the federal gov-

ernment, so I didn’t have to wait

for help.”

Kokomo Mayor Tyler Moore

said the Ventec operation has

once again shown how well

Howard County workers and

residents respond when needed.

“It’s both encouraging and

inspiring to have the rest of the

nation see what we have going

on here and seeing us support

the efforts against coronavirus,”

he said.

PRODUCTION CONTINUES

The government contract may

have been fulfilled, but that isn’t

the end of ventilator production

in Kokomo.

GM formally turned over oper-

ational control to Ventec, which

will continue manufacturing

operations inside the local GM

plant to fulfill ongoing orders for

its VOCSN critical care ventila-

tors.

Dan Flores, manager of GM

corporate news relations, said

in a previous interview the

company will lease the space to

Ventec so it can continue opera-

tions in the city.

He said there were around 800

workers building ventilators at

the facility before GM handed

over operations, including 70

full-time hourly GM employ-

ees who are expected to return

to their previous jobs or go on

layoff.

Ventec said it is now working

quickly to fulfill ongoing orders

for its ventilators, but operations

at the Kokomo facility will be

dynamic. The company will also

continue producing the machines

from its headquarters in Bothell,

Washington.

Chris Brooks, Ventec’s chief

strategy officer, said in a

previous interview that even

though the federal government

order is fulfilled, the demand for

ventilators continues to grow as

the pandemic drags on.

“The virus continues to

spread,” he said. “The infec-

tion rates continue to go up. As

more people become infected,

until there is a cure or a vaccine,

some of those people will get

seriously ill and will ultimately

need a ventilator. We can say

that things haven’t slowed down.

Demand is still very strong for

ventilators.”

Brooks said ventilators

produced in Kokomo will now

be made for direct orders from

state governments, hospitals,

home-care companies and other

entities.

Ventec CEO Chris Kiple said

the hope is that mitigation efforts

will stop the spread of the virus,

but until that happens, the

company is “committed to main-

taining increased production

capacity for as long as it is needed

to ensure front-line healthcare

workers have the tools necessary

to save lives.”

FIGHTING THE PANDEMIC

KOKOMO MANUFACTURING CONTRIBUTES TO NATION’S VENTILATOR SUPPLY

Vice President Mike Pence is greeted during his visit to Kokomo

on the tarmac at Grissom Air Reserve Base by Indiana Gov. Eric

Holcomb and others.

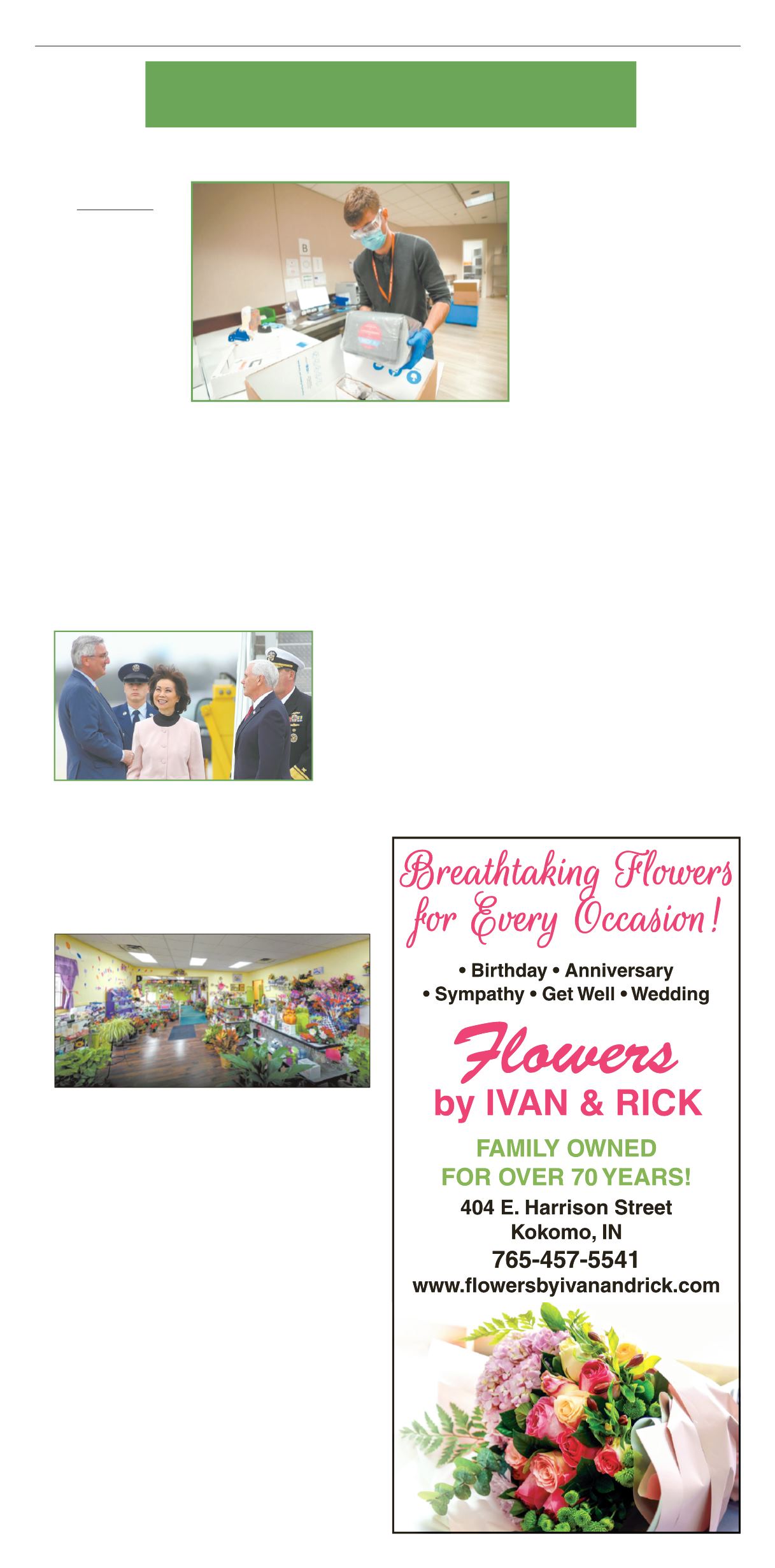

General Motors

and Ventec Life

Systems team

members sign

the boxes before

delivering the

final group of

V+Pro critical

care ventilators

to complete

the 30,000-unit

order for the

U.S. Department

of Health and

Human Services.

(

Photos by AJ Mast

for General Motors

and Ventec)

Flowers by Ivan & Rick

keep flower legacy alive

PAID ADVERTISEMENT